Fact is that sodium silicate forms a transparent film after drying. This film is found to display both adhesive and sealant properties.

- Applying a thin layer on the surface of a metal, fiberglass, paper or other fibrous material before adhering another piece will form a tight inorganic bond between the two items. The adhesion not only stays optimum but is also resistant to moisture and high temperatures.

- Water glass can be applied on concrete, stucco or plaster surfaces (after the initial cure) to seal the porous materials. The surface also becomes more wearable and water repellent.

- Some use sodium silicate to preserve food items like eggs, which can then last for a full year.

- Artists use sodium silicate to make a shell mold for blanket molds. The liquid layer will harden on drying, thus providing firmness to flexible molds. This will also render the mold surface impermeable, thus protecting the integrity of the mold. During casting, the mold will neither absorb the casting material nor leak in any manner.

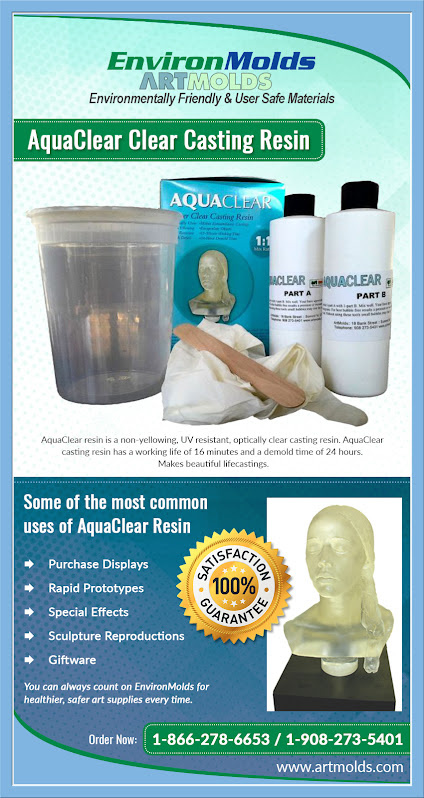

Artmolds Sodium Silicate is easy to apply and a single coat should do the job most of the time. It dries quickly to form a tight and permanent bond. It is non-toxic and free of odors too.

The best part is that it gives a transparent finish and will not affect the color or detailing of the mold in any manner. However, the silicate film can be made semi-opaque by adding fillers like clay. Using alkali-resistant options like titanium oxide or aluminum pigments will make the coating completely opaque. Artists usually mix titanium oxide to get a white hue, lime-free iron oxide for red, chrome oxide for green, ochre for yellow or ultramarine for a blue hue. Adding grease-free carbon black will make the silicate coat black while umbers or siennas can be used to make it brown.

The brand does not really matter as all sodium silicates deliver the same results. The prime difference is whether it is available as a powder or aqueous solution. In liquid form, the concentration can vary from one product to another. The powder has to be liquified by adding distilled water.

Aqueous water glass can be easily sourced from EnvironMolds at https://www.artmolds.com/artmolds-sodium-silicate.html