Understanding Resin Casting:

Resin casting is an art form that involves pouring liquid resin into a mold to create a solid, detailed replica of the mold's interior. This technique has gained popularity for its ability to preserve fine details, making it an ideal choice for crafting intricate sculptures, jewelry, and various artistic projects. The magic happens when the resin cures, transforming from a liquid into a solid masterpiece.

The Power of Polyurethanes:

It plays a pivotal role in the world of casting, bringing a myriad of benefits to artists. These materials exhibit excellent flexibility, durability, and resistance to abrasion, making them perfect for creating long-lasting, high-quality art pieces. The versatility of this allows artists to experiment with different textures, colors, and finishes, pushing the boundaries of their creativity.

Mastering the Art:

To embark on a casting journey with polyurethanes, artists must first choose the right materials. High-quality molds and polyurethane resins are essential for achieving stunning results. It's crucial to follow proper mixing ratios and application techniques to ensure a smooth and successful casting process.

Exploring Creativity:

One of the most exciting aspects of resin casting is the ability to experiment with various additives. Pigments, dyes, and metallic powders can be introduced to the resin mixture, allowing artists to customize the appearance of their creations. This opens a world of possibilities, from vibrant, translucent sculptures to shimmering, metallic-infused jewelry.

Overcoming Challenges:

While resin casting with polyurethanes offers boundless creative opportunities, it's not without its challenges. Artists may encounter issues such as air bubbles, uneven curing, or color inconsistencies. However, these hurdles can be overcome with practice, experimentation, and a keen understanding of the materials used.

Conclusion:

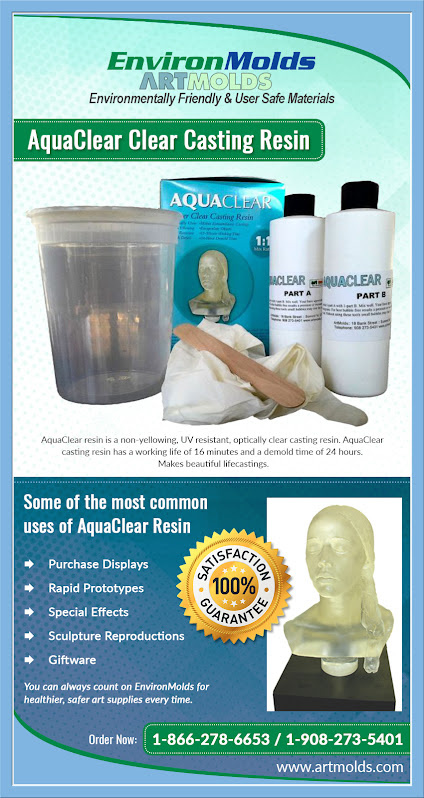

Within the realm of artistic expression, the use of polyurethanes in resin casting serves as a portal to boundless creative possibilities. As artists delve into the world of molding and casting, the quality of materials becomes paramount. For those seeking excellence in their artistic pursuits, Artmolds provides top-notch products that elevate it to new heights. Explore the vast array of molds at https://www.artmolds.com/, and unlock the full potential of your artistic vision.

Ready to elevate your artistry with the finest casting materials? Get in touch with us now to begin a creative adventure like never experienced before. Set free your imagination and transform your artistic visions into reality.