For sculptors and artists, turning creative visions into tangible masterpieces requires not just skill and inspiration, but also the right materials and techniques. In the world of three-dimensional art, mold making stands as a crucial process that bridges imagination and reality. ArtMolds has established itself as a premier destination for artists seeking professional-grade mold making materials and supplies that enable them to bring their artistic visions to life.

The Art and Science of Mold Making for Sculptures

The journey from concept to creation in sculptural art often involves intricate mold making processes. Whether working with clay, wax, or other mediums, artists rely on high-quality mold making materials to capture every detail of their original work. These materials serve as the foundation for reproducing sculptures with precision and consistency.

Understanding Professional Mold Making Solutions

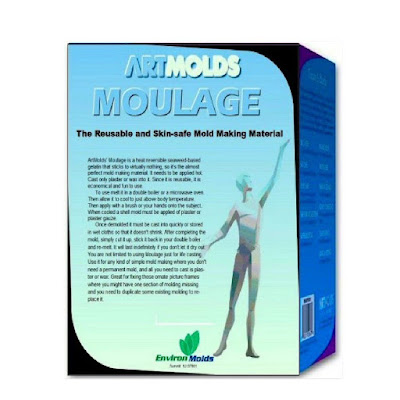

Professional artists understand that the quality of their mold making materials directly impacts the final result. ArtMolds offers a comprehensive selection of silicone rubbers, release agents, and casting materials that cater to various artistic needs. These materials are specifically formulated to capture intricate details while ensuring durability and longevity.

Elevating Artistic Excellence with Premium Artist Mold Supplies

The success of any sculptural project often hinges on the quality of mold making supplies used. ArtMolds provides artists with:

Professional-Grade Silicone Rubber

High-performance silicone rubber compounds offer exceptional detail reproduction and durability. These materials are perfect for creating complex molds that can withstand multiple castings while maintaining dimensional stability.

Advanced Release Agents

Specialized release agents ensure clean separation between mold and casting, preserving fine details and extending mold life. These products are essential for achieving professional results in any mold making project.

Innovative Casting Materials

From polyurethane resins to specialized concrete compounds, ArtMolds supplies materials that enable artists to explore various finishing options and achieve their desired aesthetic outcomes.

Empowering Artists Through Technical Excellence

Beyond providing superior mold making materials, ArtMolds stands out through its commitment to technical support and education. The company's expertise helps artists navigate complex projects and overcome technical challenges in their creative process.

Customized Solutions for Unique Projects

Every artistic vision is unique, and ArtMolds recognizes this by offering personalized guidance in selecting the right mold making materials for specific projects. This tailored approach ensures artists can achieve their desired results efficiently and effectively.

Advancing Artistic Innovation

The world of mold making continues to evolve with new technologies and techniques. ArtMolds stays at the forefront of these developments, constantly updating its product lineup to include the latest innovations in mold making materials and processes.

Conclusion

ArtMolds has established itself as more than just a supplier of mold making materials – it's a partner in artistic creation. By providing premium-quality materials, expert guidance, and innovative solutions, ArtMolds helps artists transform their creative visions into reality. Visit https://artmolds.com/ to explore our comprehensive range of professional mold making supplies and start bringing your artistic vision to life today.

Ready to elevate your sculptural art? Experience the ArtMolds difference – where quality meets creativity.