When it comes to the resins, polyurethanes are the most popular and versatile of the lot. Here is a look at the properties and benefits of polyurethane resins which work in their favor for making molds and casts.

Resins are the most commonly used type of casting materials. While synthetic resins are of different types with specific properties and uses, the polyurethane ones turn out to be the most diverse and versatile of the lot.

When it comes to polyurethane resin casting, there are options like fast-setting resins, slow-setting resins, clear resins, opaque resins, foaming resins, semi-flexible resins and more. These are two-part formulas that are usually mixed in equal quantities to form a hard and durable plastic.

After casting, the resin sets quickly and can be demolded in a short period itself. There is minimal shrinkage in the process and it displays heat resistance as well. Again, note that the resins lend themselves well for casting very small and thin-walled items which still come with high stability. It sets quickly and can be demolded in about 15 to 20 minutes itself.

The best part is that the resin is receptive to additives like fillers, color pastes and even inhibitors. Water clear casting resins are commonly used for making jewelry like pendants, earrings and bracelets by encapsulating leaves, flowers, buttons, stones, pictures and other keepsake items.

It is noteworthy that the finished polyurethane casts display excellent chemical, oil and grease resistance. Even the abrasion resistance properties are exceptional which ensures that the casts do not tear easily.

However, artists need to keep in mind that polyurethane resins tend to be sensitive to moisture and ultraviolet light. The latter can even cause yellowing, especially in the water clear resins. It also emits a strong odor during the curing process which can become a health hazard.

Special care has to be taken in the pouring as clear resins are prone to bubbles. Casting in a pressure pot will suffice here as the pressure compresses the trapped air till the resins set to a hard plastic, not leaving any space for the bubbles to expand once again.

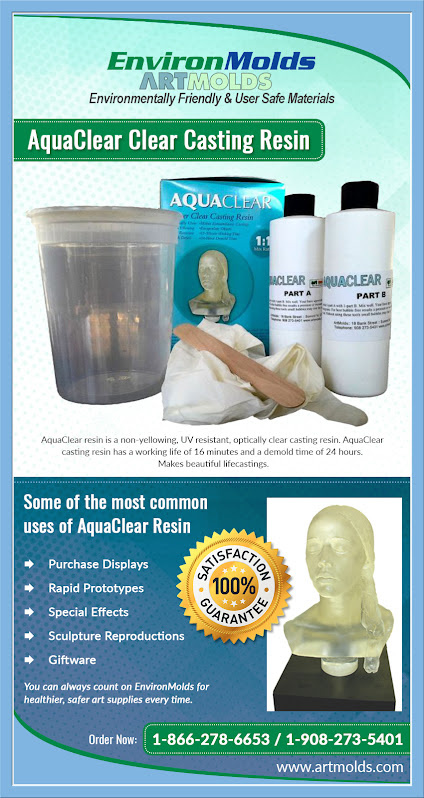

When it comes to AquaClear Clear Casting Resin, it can be easily sourced from EnvironMolds. This is a storehouse of all types of materials, supplies and equipment for making molds, casts and life casts. For instance, it is not just about the resins alone, the website also provides access to resin pigments, medium and more. Additionally, there are photo luminescent pigments and a complete line of skin-safe body paints as well.

0 Response to "The Essence That Makes Polyurethane Resins What They Are"

Post a Comment