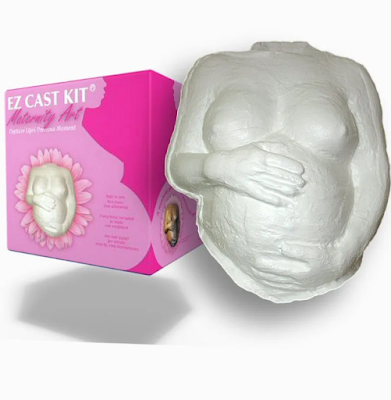

Indeed, one of the best ways to preserve the experience is making a three-dimensional representation of the pregnancy in its full glory – in the form of a belly casting.

Come to think of it, capturing the shape of the pregnant abdomen is one of the easiest aspects of making a life casting. It does not even call for an expert hand – pregnant couples easily manage to do it by themselves. And a home kit makes the process all the more simple and straightforward, given that itcontains all the materials needed to create a beautiful belly casting work of art!

Getting Inside the Maternity Life Casting Kit

The Maternity EZ Cast Kit is characterized by quality materials and easy to understand directions.Each kit contains:

- 90 yards of 4' plaster impregnated bandages-precut (6 rolls)

- 3 ounces MoldEZrelease agent

- 1 pair surgical grade rubber gloves

- 1 plastic drop cloth

To begin with, spread the drop cloth on the floor, don the rubber gloves and get going. Keep in mind that while most other kits come with around 4 rolls of plaster bandages, this one provides 50% more material. This will be more than sufficient for a 160 lbs. model and the cast will have extra strength to last for years to come. It is advisable to order an extra packet of plaster bandages per 50 lbs. additional weight.

Making the casting requires you to simply follow the directions in the guide book to the T. Roll out the bandages, cut them into strips and keep a couple of bowls of water handy. Apply the release agent on the body before starting the process.

Each strip has to be simply dipped in the water and squeezed before applying on the abdomen. Smooth out each bandage to remove air bubbles but do not press down too much either.

Build up the thickness by adding a couple of layers while keeping each layer in a crisscross fashion. Ensure that the layers are thicker on the edges. Once it has dried sufficiently, the mold can be easily demolded by squeezing the tummy a bit or inserting the fingers from the edges.

The best part is that this mold is the belly cast itself! It just has to be finished as desired.