Arts like casting and life casting begin with making a mold.

The mold forms the basic underpinning that will dictate the character

and quality of the final casting. Given the wide variety of materials

and techniques that can be used for mold making, both amateur and

experienced mold makers need to not just familiarize themselves with the

options, but also stock the studio with the requisite products.

In

addition to this, making molds will also entail the use of tools,

supplies and equipment that must be kept handy so that the mold making

process can continue without any interruptions or wastage.

Let us take a look at some of the essentials for a mold maker:

- Materials

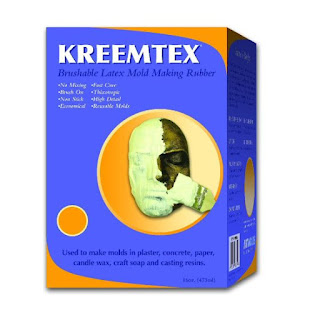

–Molds can be made with plaster, alginate, latex rubber, silicone

rubber, polyurethane resin, etc. The choice will depend on varied

factors like the master that is to be replicated, technique to be used

for making the mold, material used for casting, etc. Whichever material

is being used, it should be stocked in sufficient quantity to eliminate

the possibility of running short and having to stop the process. In

fact, it is better to have extra material on hand as the mold does not

always turn out perfect on the first attempt!

- Tools –Mold making

involves the use of very many supplies and tools, most of which mold

makers tend to take for granted. But can one afford to be stuck just

because a spatula or gloves are not available when one reaches out for

them? Always stock and replace regular items like mixing bowls and

containers, mold boxes or containment materials, release agents,

spatulas, mixers, cutting and trimming tools and measuring apparatus,

apart from gloves, aprons, safety goggles, etc.

- Equipment –When

working with rubbers and resins, a mold maker cannot overlook the

possibility of air getting trapped in the material and forming bubbles

in the mold. This will call for a vibrating table, pressure pot or

vacuum pump and chamber, depending on the materials being used.

Additionally,

the work area in the studio should be set up properly. The workspace

must be bright and well-ventilated with adequate space to move around

freely. At times, a humidifier may also be needed. There should be

sufficient storage space as some materials need to be stored in

appropriate conditions to maintain their effectiveness and longevity.

Even the supplies and equipment should be kept in drawers or shelves

rather than just being left around on the table or floor.

As a

final note, always opt for top quality mold making materials and tools

from established brands and reputed suppliers. Some of them will even

provide guidance on how to make molds, tips on what is needed and even share tricks for successful mold making!